Share this

How to Calculate the Reorder Point Formula for Ecommerce

by Kyla Friel on Nov. 3, 2023

An essential part of running an ecommerce business is finding the inventory sweet spot that results in having the right amount of stock without overstocking or running out of product. Too much inventory eats up warehouse space and can be expensive, while too little might mean you can’t meet a sudden surge in demand. It’s all about keeping your customers satisfied without wasting resources. This balance can be achieved by using the reorder point formula to calculate your business’s reorder point (ROP).

The reorder point formula helps you figure out the perfect time to order more stock by taking into account production and shipping times for your products. This way, you reorder only when you need to, avoiding extra costs from too much inventory or missed sales from running out.

In this article, we’ll explain what the reorder point formula is, how to calculate it with examples, and outline just how useful it can be for optimizing your ecommerce operations. We’ve also included a free downloadable template that automatically calculates the reorder point for your company.

What Is the Reorder Point Formula?

A reorder point (ROP), as the name implies, tells you when you should place an order for more inventory, taking into account lead times (e.g. production, shipping) so that you don’t run out of inventory. This ensures you have new stock coming in just as the last of your current inventory is selling, resulting in having the optimal amount of inventory at all times.

To calculate the ROP, you need to know how quickly the item is selling and how long a new shipment takes to arrive. You should also factor in extra stock, known as safety stock, to cover unexpected increases in sales.

As sales patterns and delivery times can change, it’s important to regularly update the ROP. This ensures you have the right amount of stock at the right time.

While you can track the ROP with basic tools like spreadsheets, many businesses use inventory management software. These systems can automatically calculate the ROP and help with ordering new stock at the right time.

You can calculate the reorder point using the following formula:

Reorder Point = Lead Time Demand + Safety Stock

Reorder Point: This is the inventory level at which a new order should be placed.

Lead Time Demand: This represents the quantity of a product you expect to sell during the period it takes for a new stock order to arrive. To determine this, you can use the formula: Daily Average Sales x Lead Time.

Safety Stock: This is an extra buffer of inventory kept on hand to protect against unexpected surges in sales, delays in incoming shipments, or other uncertainties. It helps your business avoid stockouts, keeping customers satisfied and business operations smooth.

You can calculate safety stock using various methods: a fixed quantity, a percentage of average demand, or utilizing specialized stock management systems to analyze sales patterns and potential disruptions.

How Do You Calculate the Reorder Point Formula for Ecommerce?

The reorder point calculation for ecommerce involves a few easy steps that are essential for managing your inventory. Here’s how it’s done:

- Determine Average Daily Sales: Begin by calculating the average number of units you sell per day for the product in question. This will help you understand your typical sales volume.

- Identify Lead Time: Determine the amount of time (lead time in days) it takes to receive the product once you’ve placed an order with your supplier. Reordering before you run out of stock is crucial.

- Calculate Lead Time Demand: Multiply your average daily sales by the lead time to understand how many units you’ll sell during the period it takes for new stock to arrive.

- Consider Seasonal Fluctuations: If your product sees increased demand during certain times of the year (like winter or summer), determine the maximum daily sales during these peak periods.

- Determine Safety Stock: Using the seasonal fluctuation data, estimate how much extra stock you might need to account for unexpected spikes in sales. This “buffer” helps ensure you won’t run out during peak periods.

- Calculate the Reorder Point: Add together the lead time demand + safety stock to get your reorder point. This is the inventory level at which you should place a new order.

Reorder Point Formula Example for Ecommerce

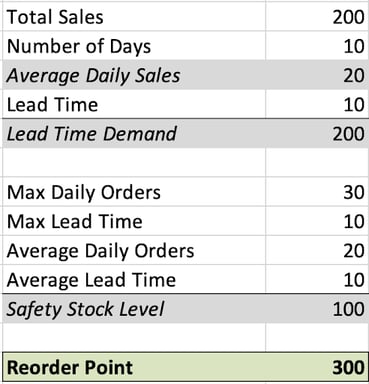

Winter Wonderland sells a popular snow globe that experiences heightened demand during the winter months.

Average Daily Sales

- They typically sell 20 snow globes per day.

Lead Time

- It takes 10 days for new stock to arrive after placing an order.

Lead Time Demand

- 20 snow globes/day×10 days=200 snow globes

Seasonal Fluctuation

- During winter months, sales can spike up to 30 snow globes per day.

Determine Safety Stock

- Safety Stock Level=(Max Daily Orders×Max Lead Time)−(Average Daily Orders×Average Lead Time)

- =(30 snow globes/day×10 days)−(20 snow globes/day×10 days)

- =(300 snow globes)−(200 snow globes)

- Safety Stock Level=100 snow globes

Reorder Point

- Lead time demand + Safety stock

- 200+100=300 snow globes

The ROP is 300. When Winter Wonderland’s stock levels for the snow globe drops to 300, it’s time to place a new order to ensure they won’t run out during the peak season.

Reorder Point Formula Template

You can download our free Inventory Management Calculator template to easily calculate the reorder point for your ecommerce business. The template also comes equipped with calculators for ending inventory and the inventory turnover ratio.

Inventory Days

Another key factor in determining optimal stock levels is what is known as “inventory days.” Inventory days, also known as “Days in Inventory” or “Days Sales of Inventory (DSI),” is a measure of how long a company’s current stock of inventory will last based on sales velocity. It’s an important concept because it helps businesses understand the average time it takes to turn their inventory into sales.

When used alongside the reorder point formula, days in inventory give you a clearer understanding of how quickly your products move. Knowing this, you can fine-tune your reorder point to better match your sales pattern, ensuring that new stock arrives just in time to replace items that are selling out.

Another way to think about inventory days is, if you know it takes two weeks for an order to arrive from your supplier and then be processed, you need to make sure that you’re placing that order before you get to 14 days of inventory on hand.

If you have a high number of inventory days (the number of days your product sits in inventory before being sold), it indicates that your stock is turning over slowly. This may suggest overstocking or lower demand for that product. Conversely, a low number of inventory days might indicate a fast turnover, suggesting high demand or possibly understocking.

These are the steps to calculate the Day Sales of Inventory (DSI):

- Find your ending inventory value for a specific time period.

- Determine your cost of goods sold (COGS) for that same period.

- Use the total number of days in the period, which is often 365 for a year.

Now, apply the following formula:

Inventory Days = (Ending Inventory / COGS) x Number of Days

Benefits of Using the Reorder Point Formula for Ecommerce

There are several reasons why the reorder point formula is essential for ecommerce, such as:

Avoiding Stock Shortages

Good stock management ensures you always have enough products to meet customer demand. Running out of stock means potential missed sales, backorders, or disappointed customers. When people can’t get what they want, they might look elsewhere, leading to lost sales and potentially harming your reputation.

Maintaining Optimal Inventory Levels

It’s not just about avoiding shortages; it’s also about not overstocking. Holding too much inventory occupies valuable storage space and could lead to increased inventory costs. Over time, some products might become obsolete or go out of style, forcing businesses to sell at reduced prices, which affects profits.

This also helps improve cash flow. By avoiding overstocking, businesses can better allocate financial resources. Money isn’t tied up in excessive inventory, allowing it to be invested in other growth areas or kept as reserves.

Keeping Customers Satisfied

Happy customers are the foundation of any successful business. By ensuring consistent stock levels, you ensure a smooth shopping experience, making it more likely customers will return and recommend your store to others.

Minimizing Storage Costs

While it might be tempting to order more stock to ensure continuous availability, this can lead to increased storage costs. Warehouse space isn’t cheap, and you pay for every inch. Using the reorder point formula helps you optimize inventory levels, ensuring you’re not overspending on storage.

Streamlining Business Operations

Managing a business comes with numerous challenges. Implementing effective inventory management systems and practices, like the reorder point formula, simplifies one aspect of your operations. It allows for better planning and efficient decision-making, freeing up time and resources for other essential tasks.

Enhanced Demand Forecasting

As businesses continue to use and refine their reorder point formula, they gather more data on sales trends, helping improve demand forecasting accuracy. This makes future inventory planning even more effective.

Challenges and Solutions in Implementing the Reorder Point Formula

The reorder point formula is a powerful tool for inventory management. However, implementing it comes with its own set of challenges. In this section, we’ll explore some typical hurdles that ecommerce businesses may encounter. We also provide solutions to ensure the formula works effectively for your operation.

Supplier Reliability

Suppliers may not always deliver on time, affecting your lead time calculations and potentially leading to stockouts.

Solution: Build strong relationships with multiple suppliers. Have a list of backup suppliers and consider signing contracts that include delivery time guarantees. Regularly review supplier performance to ensure they meet your business needs.

Changing Customer Demand

Customer demand can fluctuate due to various factors, including seasonal trends or economic shifts, potentially making it difficult to maintain accurate reorder points.

Solution: Keep a close eye on market trends and customer feedback. Utilize sales data analytics to predict demand more accurately. Adjust your reorder points regularly based on the latest sales data to accommodate changes in demand.

Forecasting Accuracy

Accurately predicting sales can be challenging, especially for new products without historical sales data.

Solution: Use a combination of market analysis, customer surveys, and competitive analysis to forecast demand for new products. As you gather sales data, refine your forecasts and adjust reorder points accordingly.

Inventory Management System Integration

Manually tracking reorder points can be time-consuming and error-prone. Integrating this formula into an existing system might be technically challenging.

Solution: Invest in an inventory management system that automates reorder point calculations. Many modern systems can integrate with your sales platforms and update reorder points in real-time as sales data and lead times change. You could also outsource your logistics, including inventory management, to a partner. Using the services of a Third-Party Logistics (3PL) provider can handle your inventory management needs for you.

Navigating the intricacies of inventory management and complex systems can be a difficult task for any ecommerce business. Partnering with a top-rated Third-Party Logistics provider like Shipfusion can take the burden of inventory management and order fulfillment off your shoulders.

We specialize in handling order fulfillment, including all of the intricacies of inventory management, giving you back the time needed to focus on growing your business.

Our expert team uses our state-of-the-art proprietary software to monitor your inventory, manage reorder points, and ensure your products are always stocked at optimal levels. We understand the dynamics of ecommerce and are equipped to adapt to market changes quickly, helping you avoid stockouts and overstocking.

Let us handle the logistics, while you dedicate your energy to what you do best – expanding your business. Contact our fulfillment experts today to learn how our Shipfusion can help optimize your operations.

Share this

You May Also Like

These Related Articles

How To Calculate the Ending Inventory Formula for Ecommerce

Using the Weighted Average Method for Inventory

Complete Ecommerce Inventory Financing Guide For 2024

- February 2026 (3)

- January 2026 (1)

- October 2025 (1)

- September 2025 (6)

- August 2025 (8)

- July 2025 (16)

- June 2025 (22)

- May 2025 (27)

- April 2025 (27)

- March 2025 (26)

- February 2025 (26)

- January 2025 (34)

- December 2024 (16)

- November 2024 (22)

- October 2024 (21)

- September 2024 (27)

- August 2024 (9)

- July 2024 (8)

- June 2024 (5)

- May 2024 (8)

- April 2024 (7)

- March 2024 (6)

- February 2024 (6)

- January 2024 (5)

- December 2023 (3)

- November 2023 (2)

- October 2023 (5)

- September 2023 (4)

- August 2023 (2)

- July 2023 (1)

- June 2023 (4)

- March 2023 (2)

- October 2022 (1)

- September 2022 (5)

- August 2022 (4)

- July 2022 (7)

- June 2022 (4)

- May 2022 (4)

- April 2022 (6)

- March 2022 (2)

- February 2022 (1)

- January 2022 (3)

- December 2021 (2)

- November 2021 (4)

- October 2021 (2)

- September 2021 (5)

- August 2021 (4)

- July 2021 (4)

- June 2021 (3)

- May 2021 (2)

- April 2021 (3)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (4)

- November 2020 (2)

- October 2020 (4)

- September 2020 (2)

- July 2020 (5)

- June 2020 (4)

- May 2020 (2)

- April 2020 (2)

- March 2020 (4)

- February 2020 (1)

- December 2019 (1)

- May 2018 (1)

- March 2018 (2)

- February 2018 (3)

- January 2018 (3)

- November 2017 (3)

- July 2017 (4)

- March 2017 (3)

- February 2017 (5)

- January 2017 (3)

- December 2016 (4)

- November 2016 (6)

- October 2016 (6)

- October 2015 (1)

- September 2015 (1)

- June 2015 (3)

- May 2015 (3)

- August 2014 (1)

- July 2014 (1)

- March 2014 (1)

- February 2014 (1)

.png?width=3334&height=468&name=Shipfusion_Logo%20Color%20Light%20(1).png)

.png?width=2850&height=400&name=Shipfusion_Logo%20Color%20Light%20(1).png)